A basic guide to using negative thermal expansion ALLVAR Alloy washers or spacers to maintain a constant preload.

Thermal Compensating Washers for CTE Mismatch

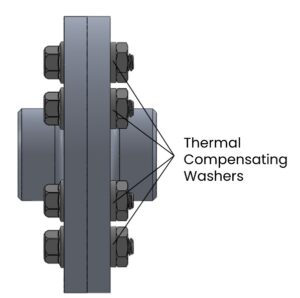

Thermal compensating washers and spacers solve thermal expansion mismatches. These spacers compensate for the differences in contraction and expansion of joint components. Well-chosen thermal compensating spacers reduce variation between the actual preloads during temperature fluctuations. Constant-force washers mean reduced fatigue in bolts and improved reliability of fastening systems. A small washer can mean the difference between an effective bolt and failure during thermal cycling.

This article is a basic guide to choose the correct length of ALLVAR Alloy 30 washers or spacers to compensate thermal mismatches. Keep reading to learn about bolt preload, how CTE mismatches impact preload, and how to use ALLVAR Alloy 30 spacers in your design.

What is preload?

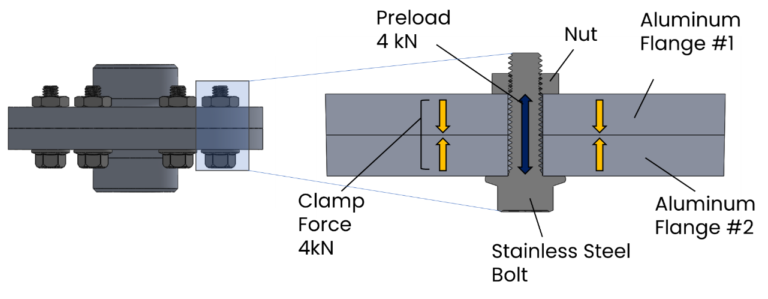

The preload is the initial tension force applied to the fastener. A torque is applied to a predetermined tension in a fastener before any external loads are applied to a joint. This torque stretches the fastener and provides a clamping force to the joint components.

Using the flange below as an example, we see that a 4kN preload applied to a stainless-steel bolt results in a clamping force equal of 4kN across the joint. If the forces on the joint stay below 4kN, the joints will stay together. Above this point, the forces will cause a gap to form between the aluminum flanges and the bolt will sustain all applied forces.

Maintaining a desired preload is critical to joint performance. A fastener requires a proper preload for a fastener to properly distribute the working load throughout the joint. Under-tightening results in insufficient clamping force. Over-tightening can lead to excessive stress, causing deformation or even failure. Proper preload improves the survivability and reliability of a joint. The initial preload is one consideration. Designers must also consider the joint’s planned operating temperatures and material properties.

Why does (Coefficient of Thermal Expansion) CTE mismatch matter?

Initial preload is generally applied at ambient temperature. As the temperature of the bolt members fluctuate, their corresponding dimensions grow and shrink due to thermal expansion and contraction. In the example above, the stainless steel bolt contracts less than the flanges while cooling. This CTE mismatch results in reduced preload and clamping force as temperatures decrease. As they heat, the aluminum expands faster than the bolt, causing it to stretch and increase the preload. In extreme cases, this could push it beyond its maximum preload limit.

As shown in a GIF in this sister blog post, the maximum and initial temperature limits often differ significantly from the initial preload. This CTE mismatch can lead to cyclic fatigue of the fastened material and even failure in extreme circumstances. ALLVAR constant force-load washers can help tackle this CTE mismatch.

How can ALLVAR Alloys help with preload?

Want to tackle CTE mismatch in your application? ALLVAR has you covered with a range of thermal compensating washers and spacers specially designed to alleviate thermal mismatch. Due to ALLVAR Alloy 30’s unique negative thermal expansion, small spacers can compensate for large CTE mismatches between cryogenic temperatures and 100°C.

If you want to learn more about how ALLVAR can solve thermal mismatches in other applications, please check out the ALLVAR Alloy optical spacers or athermal struts application pages.

Choosing the right thermal compensating washer or spacer thickness

Thermal Compensating Washer equations

The correct spacer thickness and material must be chosen to minimize loss of preload with temperature variations. This short guide will help you determine if ALLVAR Alloy constant force load washers are right for you.

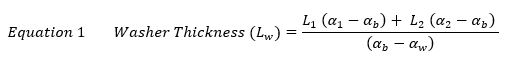

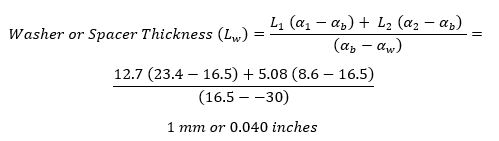

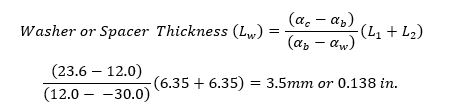

To start, we need a basic formula to determine what size washer is needed. Equation 1 assumed that the two components being joined are made from different materials. Equation 2 is a simplified version that is used if the two joined components are made from the same material.

L1 | Length of First Component |

L2 | Length of Second Component |

α1 | CTE of the first component material |

α2 | CTE of the second component material |

αc | CTE of component (if both components are the same material) |

αb | CTE of Bolt Material |

αw | CTE of Washer Material |

Example 1 - Tackle CTE mismatch of a joint with three different materials.

In this example, we want to bolt a ½” thick aluminum plate to a ¼” titanium 6Al4V sheet using an A-286 stainless steel bolt.

What ALLVAR Alloy 30 washer or spacer thickness is needed to compensate for the CTE mismatch between the components and bolt?

First, convert the thickness of each component into metric units. This yields the following.

Because the joint has two components made from different materials, equation 1 will be used to determine the spacer thickness.

In this case, 1mm of ALLVAR Alloy 30 would compensate for the differential expansion rates of the bolt and component materials. Effectively, one ALLVAR Alloy 30 washer would yield a much more constant bolt preload with changing temperatures in this joint.

L1 | Length of First Component | 12.7 | mm |

L2 | Length of Second Component | 5.08 | mm |

α1 | CTE of First Component (Al 7075) | 8.6 | ppm/°C |

α2 | CTE of Second Component (Ti-6Al-4V) | 16.5 | ppm/°C |

αb | CTE of Bolt Material (A-286) | 8.9 | ppm/°C |

αw | CTE of Washer Material (ALLVAR Alloy 30) | -30 | ppm/°C |

In the next example, we will determine the thermal compensating washer thickness needed for a fastener joining two components made of the same material.

Example 2: Aluminum 6061 Flanges with Low Temperature Bolts

In the second example, we will join two 0.25” thick aluminum flanges with ASTM A320 L7 bolts made for low temperature performance. Since the flanges fastened together are both made from the same material, we can use Equation 2 to determine the correct spacer thickness.

First, convert the thickness of each component into metric units. This yields the dimensions in the following table.

L1 | Length of First Component | 6.35 | mm |

L2 | Length of Second Component | 6.35 | mm |

αc | CTE of Flange Component (Al 7075) | 23.6 | ppm/°C |

αb | CTE of Bolt Material (A-320) | 12 | ppm/°C |

αw | CTE of Washer Material (ALLVAR Alloy 30) | -30 | ppm/°C |

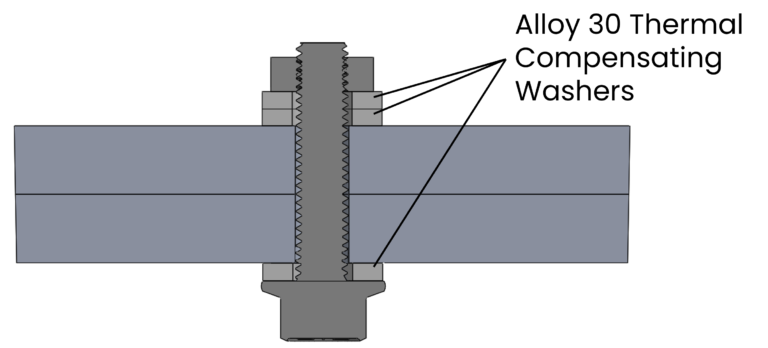

In this case, 3.5mm of ALLVAR Alloy 30 compensates for the differential expansion rates of the bolt and component materials. ALLVAR can provide a custom thickness 3.5mm spacer or stack multiple washers in series. The diagram to the left shows three #10 washers in a stackup. These three washers were enough to athermalize the joint.

Additional reading about preload

Want to learn more about preload requirements? For further reading on this subject, please see SAE AIR 1754B Washer, Thermal Compensating, Metric Series. This is the standard of record for thermal compensating washers.

For a complete guide on fastening systems, read NASA-STD-5020A REQUIREMENTS FOR THREADED FASTENING, SYSTEMS IN SPACEFLIGHT HARDWARE. Section 43.1 is particularly useful for calculating the maximum and minimum preload.

Thermal Compensating Washer or Spacer Applications

Thermal compensating washers are important in areas where even a small shift in temperature can lead to loss of bolt preload. Whether you want to keep a constant preload to improve thermal performance of your heating system or improving the reliability of a seal, ALLVAR has you covered. Application areas include:

- Satellites and Spacecraft

- Bolted Connections

- Cryogenic Systems

- Aircraft

- Industrial piping systems

- Quantum Computing

As noted earlier, a key determination of success is the operating temperature of your application. These washers are particularly suited for operations between 100°C and cryogenic temperatures. Want to know more about the operating temperatures of ALLVAR or want more data for your application? Please reach out via our contact page. We are here to help.

Don’t forget to follow ALLVAR on our LinkedIn page, check out our YouTube page, and subscribe to our newsletter to stay up to date with our latest news and events! As a team of passionate material scientists and engineers, we would love to connect and answer any questions you may have about our revolutionary material.

got a question

FAQs about ALLVAR Alloy Washers and Spacers

Pricing varies depending on spacer thickness, custom machining requirements, diameter, and tolerancing. Washers and spacers are custom-made to fit each customer’s specific requirements. Stay tuned for info about commercially off-the-shelf washers.

Most customers require custom thickness or diameter washers and spacers for their projects. With that said, we routinely make #2 through #8 washers – please see sizes on the main constant-force load washer page.

ALLVAR Alloys have similar magnetic properties to other titanium-based alloys, which are generally considered non-magnetic.

Check out the technology page to see material properties for ALLVAR Alloy 30. Please contact us for further information.

Yes! We currently have an ALLVAR Alloy 30 material definition available for SOLIDWORKS Simulation Premium. Please follow this link to request the file and for detailed instructions.

ALLVAR Alloy 30 has a maximum operating temperature of 100°C. ALLVAR is hard at work to develop negative thermal expansions that push this limit higher. Stay tuned for more information.

You have questions. We have answers. Please check out our FAQs page for other common Q&As or reach out to us directly using the contact button.

Read more about ALLVAR Alloy Washers

Tips for Designing with ALLVAR Alloys: Simplified Thermal Design

Want to learn more about how ALLVAR alloys can help with your thermal design? Find these tips, tricks, and rules of thumb to start designing