Ultra-Stable Struts

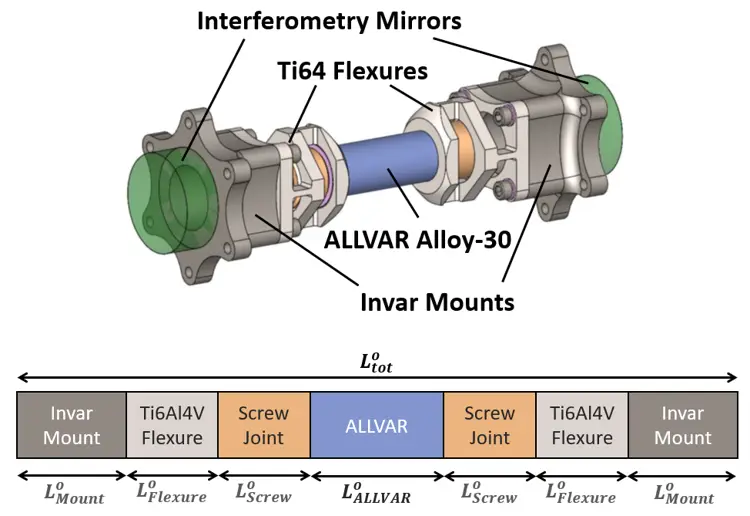

Ultra-Stable ALLVAR Alloy athermalized struts eliminate the need for costly and long-lead telescope components by compensating for positive CTE of other materials. This tunable CTE innovation flips the design paradigm on its head by enabling telescope engineers to dictate a support structure’s CTE by matching materials in a specific operating temperature range, thus athermalizing the system.

Features

ALLVAR Alloys offer a new material solution for thermally stable structures. ALLVAR Alloy 30:

- Has a axial Coefficient of Thermal Expansion (CTE) of -30.0ppm/°C at room temperature.

- Has a positive CTE in the radial direction (similar in magnitude to Aluminum), allowing for compliant mounting of optical elements.

- Negative Thermal Expansion (NTE) can control the CTE of a component. By selecting the correct length of NTE alloy relative to other components, the CTE of the overall strut length is tunable to a specific value, including zero.

- Exhibits mechanical and material properties similar to other Titanium alloys.

- Can be machined like many other metals, tolerances of ±0.001” are easily achievable.

- Available in both round bar and tube formats; ALLVAR Alloy 30 is a natural fit for the design and fabrication of strut components, lens barrels, and lens-to-focal plane stand-offs.

Value Propositions

For more cost-sensitive designs and programs, these tailored CTE rods can reduce engineering design time, simplify optic manufacturing and alignment, and offer ultra-high stability of telescope support structures . When ALLVAR Alloy 30 is used in telescope support structures, it has the following effects:

- Reduced Coefficient of Moisture Expansion (CME) effects and bake-out requirements by replacing some or all carbon fiber composite components.

- Reduced carbon fiber composite scrap components by tuning the CTE of carbon fiber tubes whose CTE is out of specification.

- Enable a design-specific zero-CTE crossing determined by the application’s operating temperature.

- In-situ CTE tunability without changing strut’s metering length.

- Increased structural stiffness by eliminating nested or tube-in-tube athermalizing designs.

Getting technical

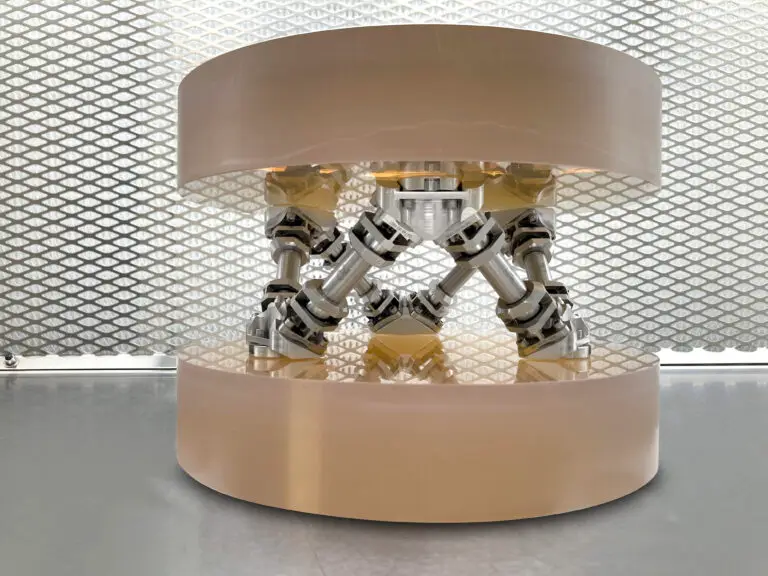

These struts were designed and manufactured as part of a NASA SBIR Phase II project titled “Ultra-Stable ALLVAR Alloy Strut Development for Space Telescopes.” The CTE and stability of each strut were measured to quantify variability between struts. A stability of 2 pm/√Hz was achieved for the individual struts with a CTE of 0.6 ppm/°C. The manufacturing consistency was very high with a standard deviation of 0.05 ppm/°C between each strut.

In order to achieve this low CTE, ALLVAR Alloy 30’s negative CTE was tuned to counteract the positive CTE of each of the other components in the series.

Ultra-Stable Strut Related Posts

Learn more about these ultra-stable struts and the work being done on this application in the ALLVAR blog series.

Products Available

ALLVAR offers a range of products that can help suit your project or program needs – either by providing semi-finished material in round bar or tube form, or fully machined parts to print. Maximum sizes are 2.25” round bar and 3.00” out diameter tube up to 10 feet in length.

ALLVAR Alloy 30 can also be machined into custom products or components best suited for your specific product or project. Our team of engineers at ALLVAR are on hand to provide design support, machine parts to print, and discuss the technical details of your project. If it is beyond our own expertise, we will collaborate with one of our many partners experienced in designing and machining these negative thermal expansion alloys. Utilizing groundbreaking materials and streamlined design strategies for your next project is sure to bring up a lot of questions. Not sure if ALLVAR is a good fit for your project? Please contact us. We would be happy to discuss negative thermal expansion Alloy 30’s applicability for your application.

Knowledge is Power

Our ALLVAR University video series offers a deeper dive into designing with ALLVAR Alloy 30. These specific videos offer more information related to the ultra-stable strut application.

Creating a Tailored Thermal Expansion Part 1 – Using ALLVAR Negative Thermal Expansion Alloys to create a target CTE.

Creating a Tuned Thermal Expansion Part 2 – Tailored Expansion with Multi-Components

Creating a Zero Thermal Expansion Part 3 -Tailoring Thermal Expansion to Achieve Zero Expansion with ALLVAR Alloys

Passive Athermalization Solutions for Optical System Alignment

Tips for Designing with ALLVAR Alloys: Simplified Thermal Design

Want to learn more about how ALLVAR alloys can help with your thermal design? Find these tips, tricks, and rules of thumb to start designing with Negative CTE Alloys today.

Unlocking the Cosmos: ALLVAR’s Role in the Nancy Grace Roman Space Telescope

ALLVAR is headed to space in a big way! Find out how ALLVAR Alloys are being used aboard the Nancy Grace Roman Space Telescope to improve thermal conductivity.

Design with Athermal Materials in Solidworks

Athermal Material design is easy with the SOLIDWORKS ALLVAR Alloy 30 material definition. Request the file here and design with negative thermal expansion today!

Matching ZERODUR®’s CTE – ALLVAR Alloy 30 enabled near zero CTE struts

ZERODUR is known for it’s zero CTE. Learn how ALLVAR Alloy 30 can help match supporting structure’s CTE to ZERODUR.

Introductory Guide to Tailored Thermal Expansion

Want to match a certain CTE? The tailored thermal expansion guide has you covered. Learn how negative thermal expansion can help here.

Creating the Future of Ultra-Stable Telescopes

Negative thermal expansion ALLVAR Alloy 30 offers a solution for the future of ultra-stable telescope requirements. Read about our current work to enable ultra-stable telescopes here.

Contact Us Today to Revolutionize Your Thermal Performance

Have an application in mind? Please let us know if you have any questions.