NTE Lens Tubes for Optic Athermalization

Passive Athermalization

Maintaining performance and structural integrity of optical systems over a wide temperature range (passive athermalization) has been a practical and technical struggle for decades. Eliminate unreliable optical performance by simply replacing traditional athermalization solutions with the only negative CTE alloy in the world, ALLVAR Alloy 30. This negative CTE innovation renders traditional design paradigms inefficient and enables smaller, lighter optical system designs that were previously impossible.

Features

ALLVAR Alloy 30 offers a new material solution for athermalized optical assemblies. This novel material:

- Has a axial Coefficient of Thermal Expansion of -30.0ppm/°C at room temperature.

- Has a positive CTE in the radial direction (similar in magnitude to Aluminum), allowing for compliant mounting of optical elements.

- Exhibits mechanical and material properties similar to other Titanium alloys.

- Alloy 30 can be machined like many other metals, tolerances of ±0.001” are easily achievable.

- Offered in both round bar and tube formats; it is a natural fit for the design and fabrication of lens stack spacers, lens barrels, and lens to focal plane stand-offs.

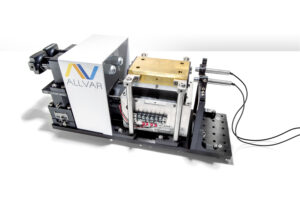

Breadboard with ALLVAR Alloy 30 SM1 Lens Tubes

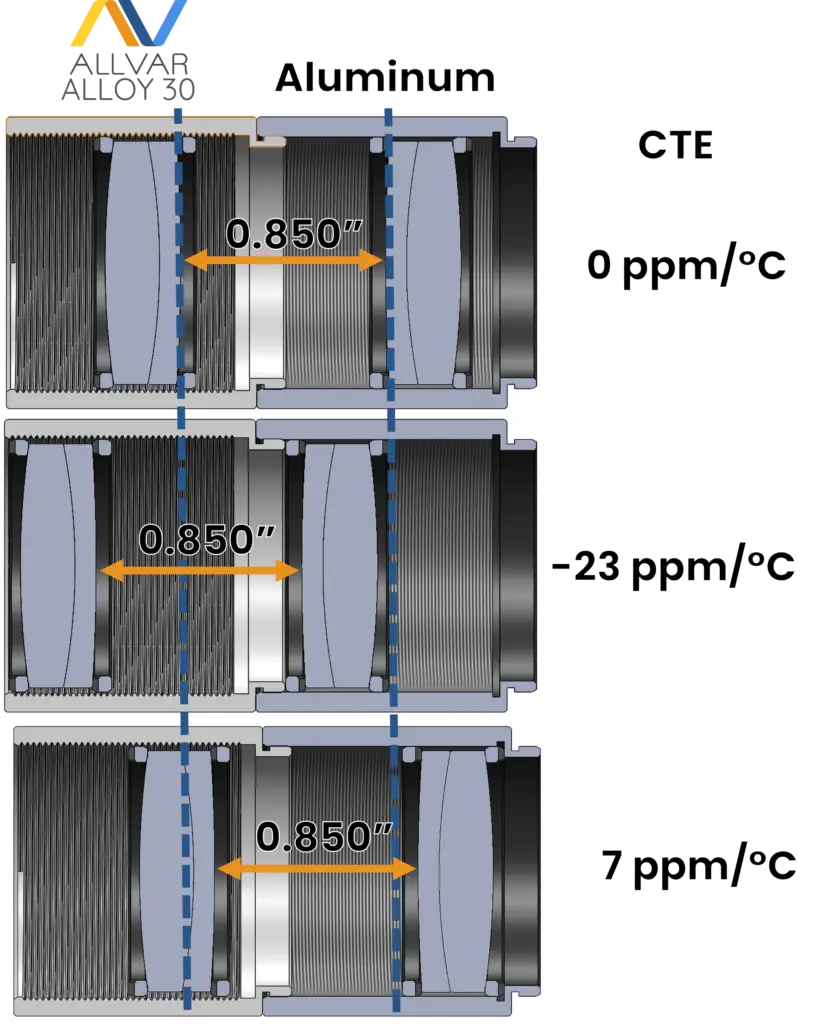

Pick the CTE that works for your design

- Enables CTE tailoring of athermal systems

- Negative CTE (-30 ppm/°C) Lens Tube

- Great for breadboarding ALLVAR Alloy 30 in your design

- Standard SM1 Lens Tube Sizing

- Stackable with standard SM1 Lens tubes (1.035″-40) threaded component

Value Propositions - Athermalization

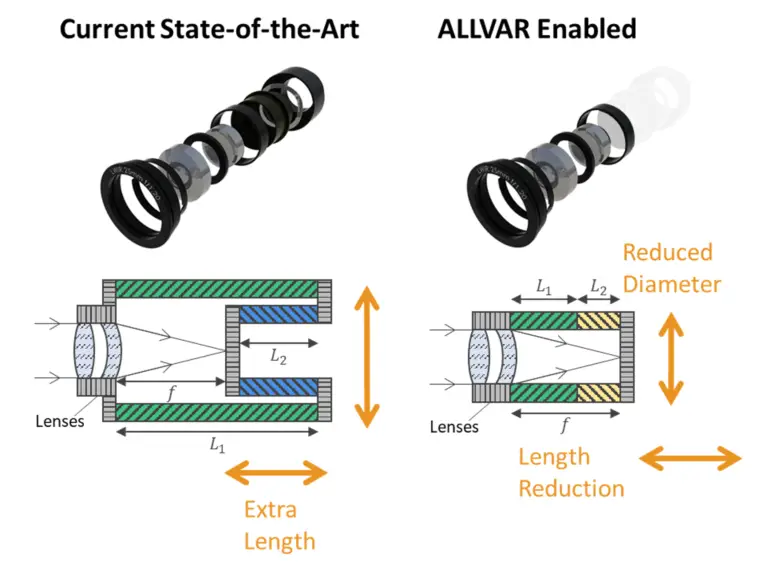

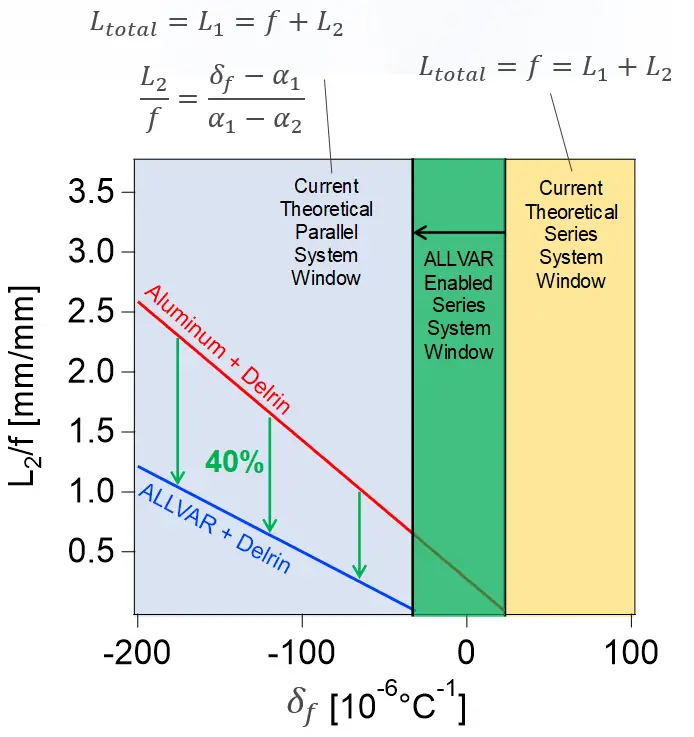

- Reduce infrared optical assembly length up to 40%.

- Reduce weight by decreasing optical element count.

- Reduce manufacturing costs and lead time by decreasing part count and design complexity.

- Increase yield by relaxing tight mechanical and optical element tolerances necessary for athermalization.

- Close the 5%-10% gap in performance at temperature between design and manufacturing.

Specifically targeting fixed-focus objectives/cameras, the addition of ALLVAR Alloy 30 can eliminate nested barrel structures and complex compensation mechanisms, providing passive mechanical athermalization for maintaining optimum image quality from -140°C to +80°C and beyond.

Smaller, lighter, athermalization of optical systems

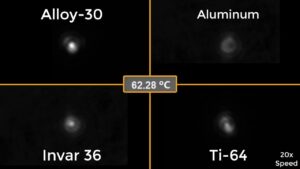

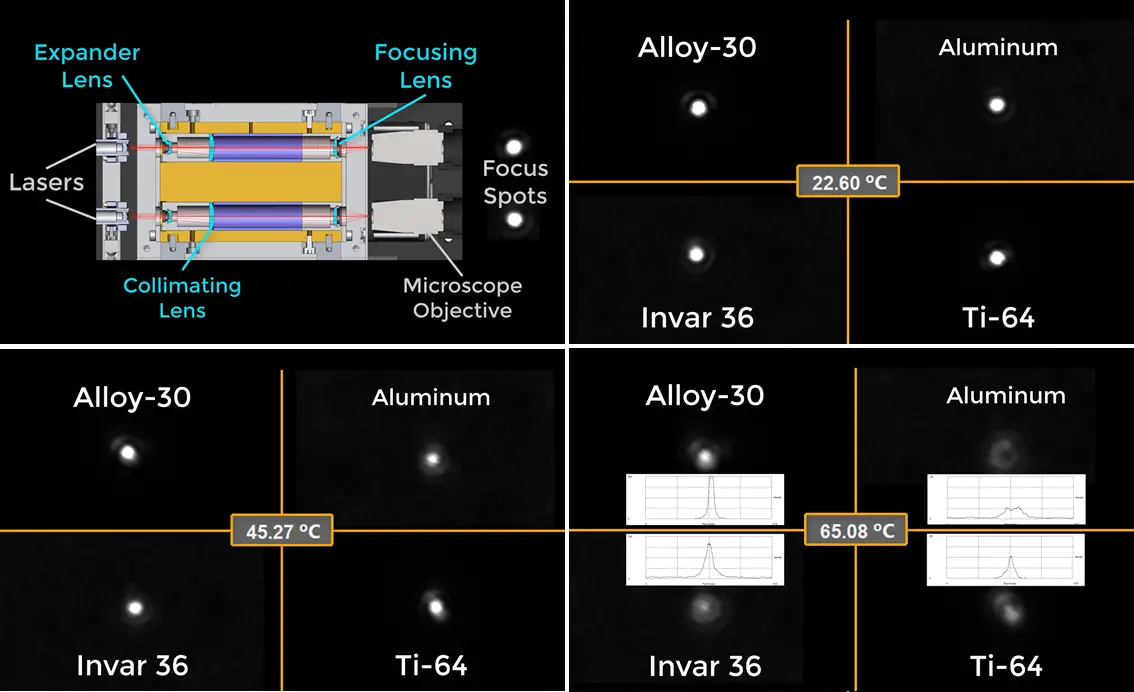

Looking at the image above, several materials were used as spacers between a set of lenses that ultimately display a spot from a laser in an image. Between ALLVAR Alloy 30, Aluminum 6061, Invar 36 and Ti-64, Alloy 30 maintains the highest peak intensity – and best focus – as the temperature increases from 22° to 65°C. Click the button above to see a full video of the demonstration.

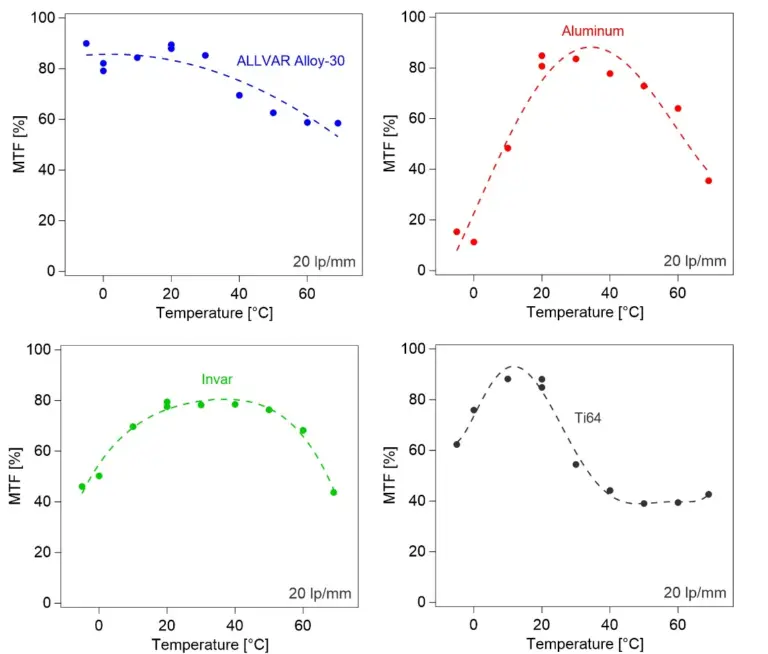

For those that prefer more technical detail, shown below are the Modulation Transfer Function (MTF) values versus temperature for each material’s image spot. The Aluminum and Ti6Al4V (Ti64) show very sharp peaks associated with rapid drop offs in performance above and below an optimal operating temperature. The Invar shows excellent stability between 20°C and 50°C, but MTF drops off well below 60% above and below this optimal operating temperature. The ALLVAR Alloy 30 material displays a much smoother response and excellent stability throughout with a small decrease from 85% MTF at -10 °C to 60% MTF at 70°C.

Products Available

ALLVAR can suit your project or program needs – either by providing semi-finished material in round bar or tube form, or fully machined parts to print. Maximum sizes are 2.25” round bar and 3.00” outer diameter tube.

ALLVAR Alloy 30 can be machined into custom products or components best suited for your specific product or project.

Not sure if ALLVAR is a good fit for your project? Please contact us. We offer a wide range of design services and machining, and we would be happy to discuss negative thermal expansion Alloy 30’s applicability for your application.

Athermal Optics Related Articles

Learn more about the work being done on optics in the ALLVAR blog series.

The Evolution of Athermal Design

Athermal design owes its foundations to an 18th century clockmaker’s designs. ALLVAR Alloys will help you revolutionize your design.

Design with Athermal Materials in Solidworks

Athermal Material design is easy with the SOLIDWORKS ALLVAR Alloy 30 material definition. Request the file here and design with negative thermal expansion today!

Introductory Guide to Tailored Thermal Expansion

Want to match a certain CTE? The tailored thermal expansion guide has you covered. Learn how negative thermal expansion can help here.

ALLVAR Awarded SBIR Phase I Contract

ALLVAR has been awarded a US Air Force SBIR Phase I contract. This Phase I contract will allow ALLVAR to connect and partner with US AF stakeholders.

Negative CTE, Positive Results: Exploring Athermalization Solutions for Defense Optics

Athermalization enabled for defense optics. ALLVAR Alloys benefit defense by enabling smaller, lighter systems with improved lead time and reduced scrap.

Unobtanium Goes to Work!

Learn how ALLVAR can help athermalize optical systems in this short article.

Contact Us Today to Revolutionize Your Thermal Performance

Have an application in mind? Please let us know if you have any questions.