By: J.A. Monroe

Tackling Athermalization with negative thermal expansion

The struggle to keep lenses in focus while withstanding temperature change is nothing new. As an engineer, you may not care why temperature change pushes a lens assembly you are designing out of focus, you just care about finding a solution.

What happens when you’ve tried all of your traditional solutions and you still need two lens cells to come closer together when temperature increases? You could create a barrel-in-barrel design, but that would add complexity and component count while making the whole system larger and heavier. There is a simpler solution with a material that shrinks when heated.

ALLVAR Alloy 30, the first commercially available material with negative thermal expansion.

Negative Thermal Expansion at Work

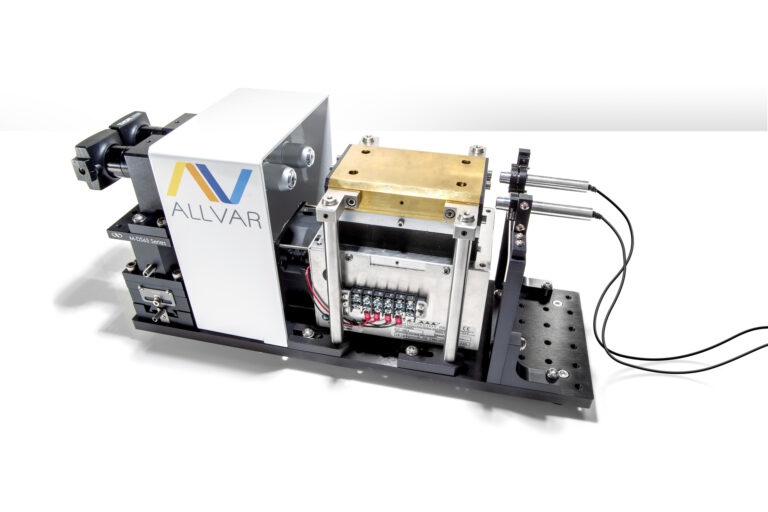

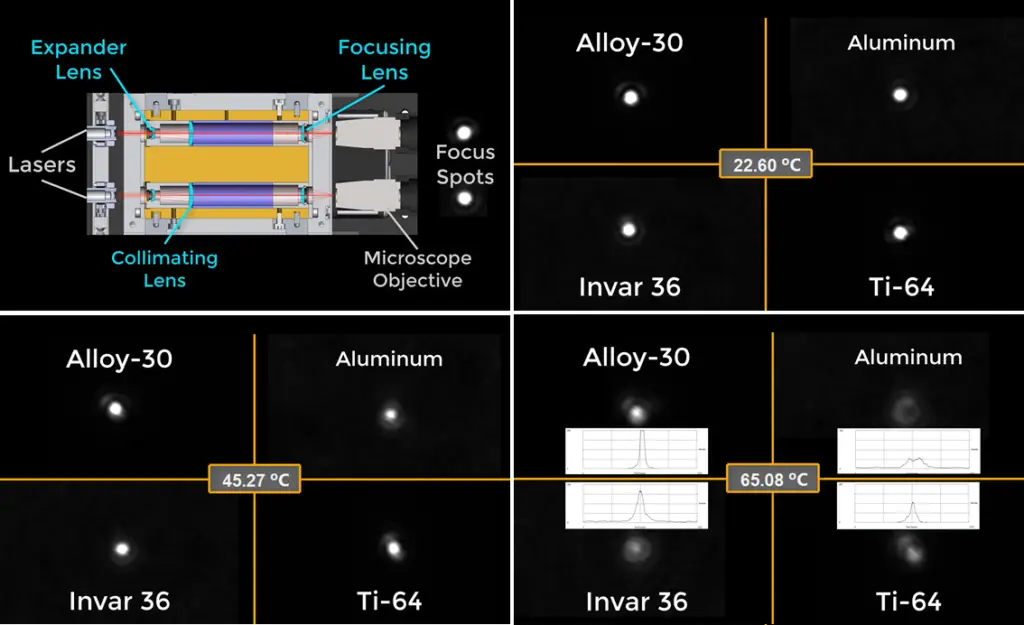

While modeling and calculations are helpful, they pale in comparison to seeing actual results. Above is an optic demonstrator which includes a lens assembly designed to require a negative thermal expansion material between two lens cells in order to maintain optimum focus. We used it to compare the performance of ALLVAR Alloy 30 to other metals like Aluminum, Titanium, and Invar.

Looking at the image below, ALLVAR Alloy 30 maintains the best focus as the temperature increases from 29° to 65°C. Watch the full video here.

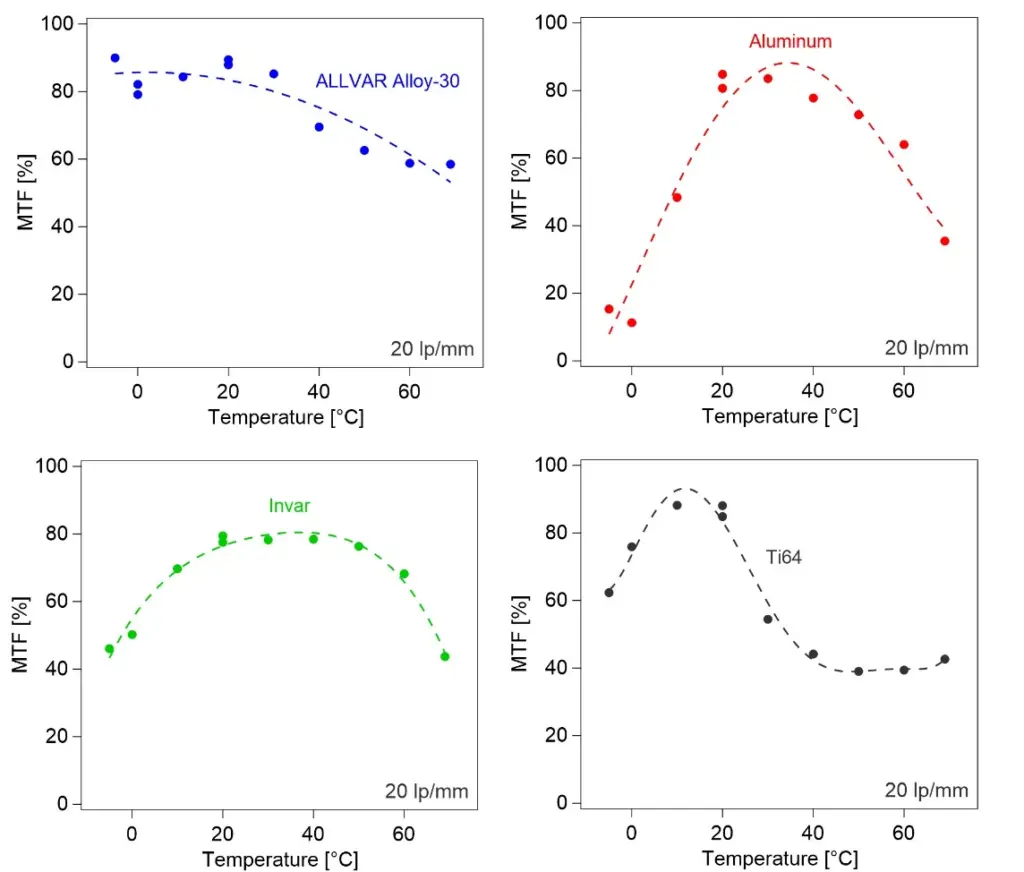

Exploring the technical details

For those that prefer more technical detail, shown below are the Modulation Transfer Function (MTF) values versus temperature for each image spot for the four materials tested. The Aluminum and Ti6Al4V (Ti64) show very sharp peaks associated with rapid drop offs in performance above and below an optimal operating temperature. The Invar shows excellent stability between 20°C and 50°C, but MTF drops off well below 60% above and below optimal operating temperature. The ALLVAR Alloy 30 material displays a much smoother response and excellent stability throughout with a small decrease from 85% MTF at -10 °C to 60% MTF at 70°C.

With ALLVAR Alloy 30, you have another tool in your engineering toolbox. The novel metal that shrinks when heated and expands when cooled. Solve your focusing dilemmas today.