A new tool in the thermal design toolbox

Sometimes the current state-of-the-art design just doesn’t cut it. With some innovative thinking and a fresh approach to design, ALLVAR can help you solve your toughest thermal design challenges.

You might consider ALLVAR Alloys if your design:

- Needs passive athermalization

- Must perform across a wide temperature window

- Has tighter than practical tolerances due to thermal stability requirements

- Requires reduced size, weight, or power

Changing the athermal design paradigm

Simply put, ALLVAR Alloys “do the opposite” of what other materials do which can take some time to fully grasp. Designing an athermalized system with ALLVAR Alloys often challenges engineers and designers to update their design processes. What used to be a constant – the coefficient of thermal expansion (CTE) – is now a variable under the designer’s control. This tunability enables new ways to tackle problems caused by thermal expansion.

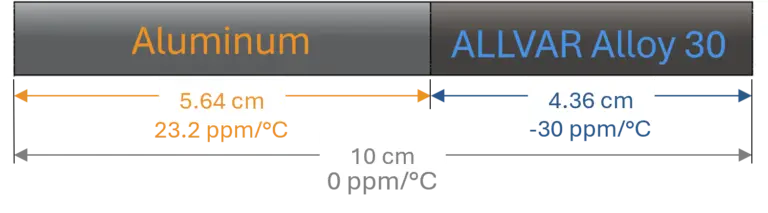

So, what does this mean for thermal design? Let us envision we want to create a structure that does not expand or contract with temperature changes. We would use lengths of positive expansion aluminum and negative expansion ALLVAR Alloy 30 connected end-to-end . Aluminum’s CTE is approximately 23 ppm/°C while ALLVAR Alloy 30’s is -30ppm/°C; about 1.3 times the rate of aluminum.

The example to the left illustrates how ALLVAR Alloy 30 can compensate for positive CTE materials., In this case, we want to hold a distance of 10cm with a strut. You would need 4.36 cm of ALLVAR Alloy 30 and 5.64 cm of aluminum. This combination yields a near net zero thermal expansion. If you’re interest in learning more, we’ve created a short guide to help you perform these calculations yourself.

Passive Athermal Optics: Basic tips for using ALLVAR Alloys

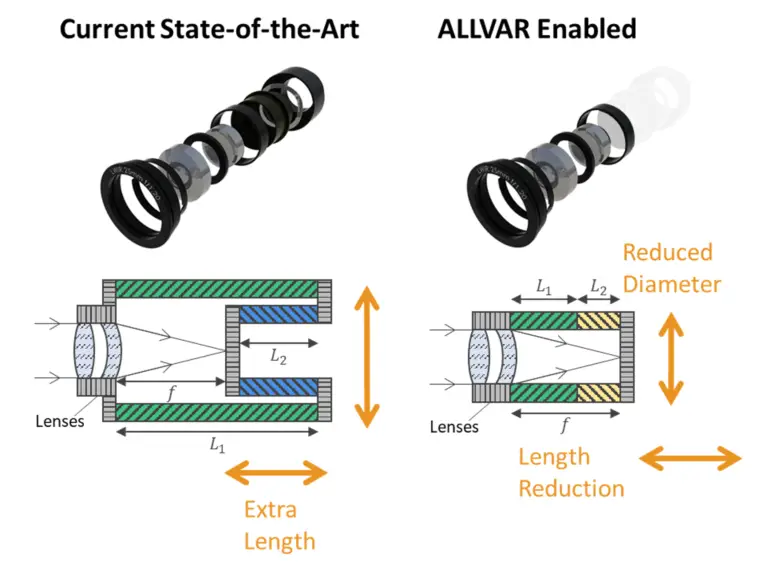

ALLVAR Alloys are unique because of their negative thermal expansion property. A length of the ALLVAR Alloys lens tube used as a lens spacer will shrink in its length as temperature increases. Combining ALLVAR Alloys with aluminum lens tubes in the right way can enable a lens housing to match a specific thermal focal shift caused by changes in lens geometry and index of refraction, dN/dT, with temperature.

Passive athermalization with ALLVAR Alloys can:

- Remove thermal defocus effects on lenses designed without thermal effects in mind.

- Enable another degree of freedom in your design.

- Shift the compensation of thermal defocus from the lens elements and tolerancing to the housing material.

- Reduce lens count.

- Eliminate the need for active refocusing for athermalization.

- Remove the barrel-in-barrel design (aka double-switchback, tube-in-tube, top hat, nested tube, etc.)

Offsetting forces due to temperature change? Thermal compensating washers can help.

Sometimes, you might not be as concerned with displacement, but instead concerned about mechanical stress or force over temperature. ALLVAR Alloys can help. For example, a bolted joint will experience changes in pre-load with temperature due to CTE mismatch between the bolt and bolted plate or flange. ALLVAR Alloy 30 thermal compensating washers can:

- Reduce force and stress over a wide temperature range.

- Enable smaller, lower profile, and lighter structures by eliminating the need for long compliant bolts and flexures.

- Increase structure longevity by reducing thermal cycling fatigue

A premium alloy product that can save money.

ALLVAR Alloys are premium metals with a premium price. With that said, overall cost savings are possible with careful design. Some things to keep in mind when evaluating cost:

- The cost of ALLVAR Alloys scales linearly in length, but exponentially in diameter. Three small diameter rods are usually more economical than one large diameter tube.

- Thin-walled tube is substantially more cost effective than buying round bar and hogging it out.

- ALLVAR Alloys can often reduce assembly, engineering, and design costs by enabling simpler designs.

- ALLVAR Alloys can also increase yield, reduce scrap rates, and reduce manufacturing costs by enabling looser tolerances.

- Increasing performance at temperature can enable a competitive advantage over your competition.

Design Resources

We have resources to help you design with ALLVAR Alloys. Explore the following informative articles and guides for more information.

Thermal Compensating Washers for CTE Mismatch

Learn how to use negative thermal expansion ALLVAR washers or spacers to maintain a constant preload.

Design with Athermal Materials in SOLIDWORKS

Ready to get your hands dirty designing with ALLVAR Alloy 30? Request the material definition file on this page and follow the guide to model with ALLVAR Alloy 30.

Want to create a zero or tailored CTE Structure? Learn how to tune CTE by compensating positive CTE materials with negative CTE ALLVAR Alloy 30.

CTE Mismatch in Bolted Joints – Negative Thermal Expansion Washers offer a solution!Learn how to tackle CTE mismatch – one washer at a time – with this bolted joint simulation case study.

When is the right time to reach out to ALLVAR?

Material selection is a critical step that drives system architecture so you should consider ALLVAR Alloys as early as possible in the design process. ALLVAR has resources like our SOLIDWORKs material file and Technical Specifications (by request) that will help. We also have a library of helpful ALLVAR University videos and can meet to answer technical questions. Reach out to a member of the ALLVAR team or info@allvaralloys.com with your questions. We are here to help.