The Ultra-Stable Telescope Challenge

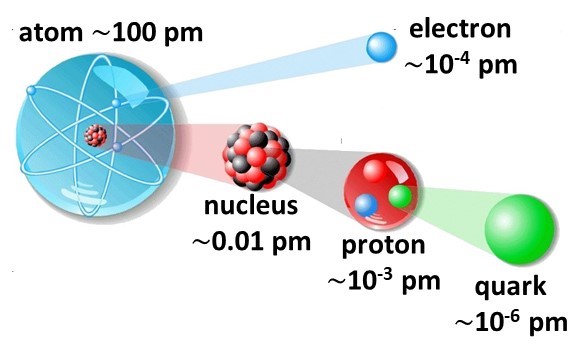

NASA’s future astrophysics mission to identify habitable planets outside our solar system, known as exoplanets, is driving the need for 10-meter class space-based telescopes (see 2020 Decadal Survey). This next generation of large telescopes, such as LUVIOR and HabEx, demand ultra-stable structures that change shape less than 10 pm rms (picometer root mean square). To put this stability requirement in perspective, 10 pm is about one tenth the diameter of an atom. This ultra-stability is needed to achieve the 10-10 contrast required for direct detection of atmospheric composition and biosignatures on distant exoplanets. A major problem is the natural expansion and contraction of telescope materials with temperature changes that can easily push a 10-meter class telescope outside the 10 pm requirement.

Unfortunately, current state-of-the-art materials developed for the James Webb Space Telescope do not meet these new ultra-stability requirements. According to the 2020 Astronomy and Astrophysics Decadal Survey, the temperature, moisture, and creep resistance of materials, such as carbon fiber reinforced composites and Invar, must be improved to close several Tier 1 technology gaps. There is a great need for new materials that can close these technology gaps to enable ultra-stable telescope missions.

Negative Thermal Expansion Offers a Solution

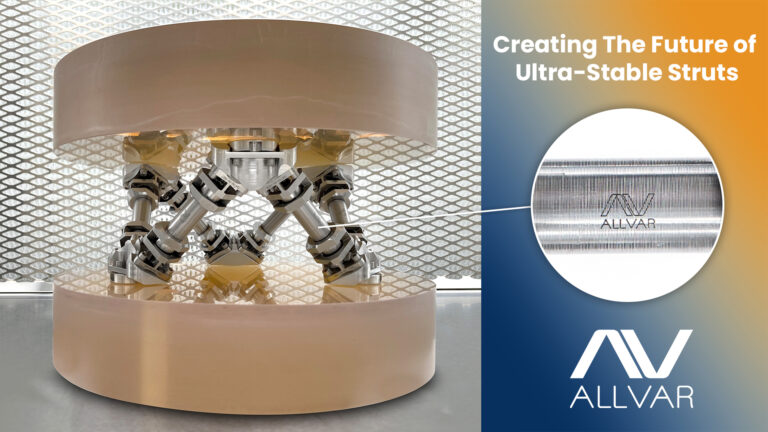

ALLVAR Alloys offer a unique solution to help close these ultra-stability technology gaps. Titanium-based ALLVAR Alloys are the only metals in the world that shrink when heated and expand when cooled, known as negative thermal expansion. This unique negative thermal expansion property allows optical designers to compensate for the natural positive thermal expansion of other materials to athermalize their applications like never before. The image at the top of the page shows a hexapod structure with ALLVAR enabled near-zero CTE struts designed to demonstrate ultra-stability. These struts were able to achieve a near-zero thermal expansion from end–to-end by tuning the strut’s overall linear CTE with the addition of a negative thermal expansion segment.

Qualifying ALLVAR Alloy 30 for Space-Based Telescopes

ALLVAR Alloys show promise for NASA’s ultra-stability needs, but there are many questions to answer about its material property performance. ALLVAR was recently awarded a NASA SBIR Phase II grant to help answer these questions. With the funding, ALLVAR hopes to generate a large data set of basic material and micro-creep properties so engineers can confidently incorporate ALLVAR Alloy 30 into their optics design.

ALLVAR Alloy 30 is currently produced in small batches of solid bar up to 2.5-inch diameter and tube up to 3.0-inch diameter. While ALLVAR has proven consistency between many heats and batches over the years, this project will produce the first large-scale data set with high statistical confidence. Successful performance of this project will improve the integration readiness of ALLVAR Alloy 30 for advanced optics applications. From space-based NASA telescope missions to optic modules on the ground, this data combined with continual quality system improvements will ensure that optical designers can rely on ALLVAR Alloys for their athermalization needs.

Testing Requirements

Ten ALLVAR Alloy 30 heats will be produced using our advanced manufacturing processes and then tested per the methods outlined in the Metallic Materials Property Development and Standardization (MMPDS) documentation. Samples will be tested by a third party to determine tension and compression, shear strength, thermal conductivity, specific heat, fracture toughness, fatigue, and creep properties. The data will then be sent to the Battelle Memorial Institute, the custodians of the MMPDS, to determine statistical material properties. The third-party data collection and analysis provides an independent review of ALLVAR Alloy 30’s material properties.

This data will be integrated into ALLVAR’s quality system and used to verify ALLVAR Alloy 30’s batch-to-batch consistency during production. Much like other NASA–funded technology, the information gathered from this project will be made available to the broader optics community so they can confidently integrate ALLVAR Alloy 30 into their designs. This data–driven process will ensure that designers can trust the consistency of ALLVAR Alloy 30 today, tomorrow, and far into the future.

Don’t forget to follow ALLVAR on our LinkedIn page, check out our YouTube page, and subscribe to our newsletter to stay up to date with our latest news and events! As a team of passionate material scientists and engineers, we would love to connect and answer any questions you may have about our revolutionary material.