A new tool for Cryogenic Design

Have you worked with a cryogenic system and ran into a thermal expansion issue? If so, ALLVAR is here to help. ALLVAR’s range of washers and custom components are purpose-built to improve performance of cryogenic applications.

Since 2018, ALLVAR has solved tough thermal expansion issues in cryogenic systems. In fact, our first introduction to cryogenics led to the launch of ALLVAR Alloy constant-force load washers. These washers were made to improve the stability of bolted joints in cryogenic assemblies, improving reliability by decreasing fastener fatigue or failure due to slipping. These washers help fasteners ‘stay tight’ regardless of the temperature by growing as other materials shrink as temperatures cool, compensating for the CTE mismatch of material

CTE Mismatch in Cryogenics

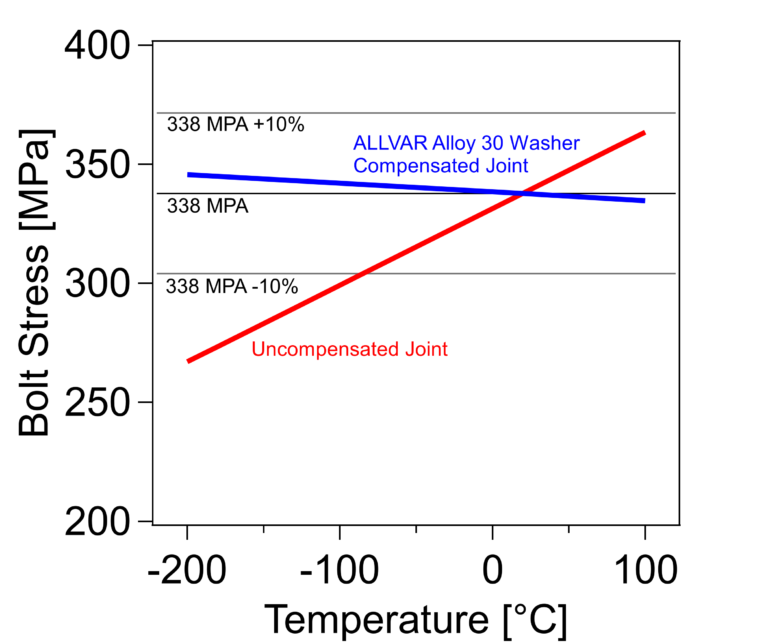

As shown in our CTE Mismatch Solution with ALLVAR Alloy Washers blogpost, an uncompensated joint’s preload, or bolt stress, changes significantly with temperature flux and is easily pushed out of +/- 10% preload safety margins. In cryogenic systems, this problem. The same joint using ALLVAR Alloy 30 washers varies only slightly across a wide 300°C temperature window as shown in the graph.

We routinely test the CTE of ALLVAR Alloys using liquid nitrogen. Our current thermal expansion testing method allows us to test thermal expansion of ALLVAR Alloys 30 down to -150°C, but ALLVAR’s applications don’t stop there. ALLVAR has successfully been used in much colder, <10 K cryogenic systems. Stay tuned for more information. CTE data for much colder temperatures is in the pipeline.

What's next for ALLVAR Alloys in Cryogenics? We need your help to decide!

To date, ALLVAR Alloys have been proposed for systems ranging from quantum computing to particle accelerators. Our understanding of the use cases for ALLVAR Alloys in cryogenics is just scratching the surface of what is possible. Do you have an application that may benefit from stabilization using ALLVAR Alloy 30? Please contact us – we would love to help.

Don’t forget to follow ALLVAR on our LinkedIn page, check out our YouTube page, and subscribe to our newsletter to stay up to date with our latest news and events! As a team of passionate material scientists and engineers, we would love to connect and answer any questions you may have about our revolutionary material.